[video:https://youtu.be/8YQIaOldDU8]

Morgan Freeman narrates this hopeful, must-watch short film about the need to solve the climate change problem. Video by the United Nations.

Source: The Daily Conversation 2014

[video:https://youtu.be/8YQIaOldDU8]

Morgan Freeman narrates this hopeful, must-watch short film about the need to solve the climate change problem. Video by the United Nations.

Source: The Daily Conversation 2014

Imagine that the average U.S. dishwasher is only 65% full when run, but you had the power to ensure that all dishwasher loads were filled to capacity. Massive water savings and reduced energy consumption come to mind, but what about less detergent use, and scaling back on the substantial resources needed to produce and transport detergent?

By replacing wood and plastic pallets with lightweight corrugated cardboard pallets, we can ensure that U.S. truck shipments are much closer to 100% than currently is the case. And yet we don’t.

Let’s change that, starting with some directional numbers:

How much is 100 billion truck miles? The equivalent of driving to Mars and back...more than seventy (70) times.

These 250 million trucks, each traveling 400 miles -- and hypothetically weighing 65,000 per truck -- will use over 1.66 billion gallons of diesel and emit nearly 170 million metric tons of CO2e(carbon dioxide equivalent) annually.

Lightweight corrugated cardboard pallets are as effective as other pallets. Photo Credit: Change the Pallet

Corrugated pallets weigh only ~10 pounds, so “changing the pallet” would lower the amount of pallet weight alone shipped each year in the U.S. by ~200 billion pounds. Doing so would theoretically save 205 million gallons of diesel and emit some 21 million fewer metric tons of CO2e annually (based on a 10% drop in fuel consumption).

While intuitive, this model does not hold in the real world, where vast CO2e reductions are driven by filling space, not reducing weight.

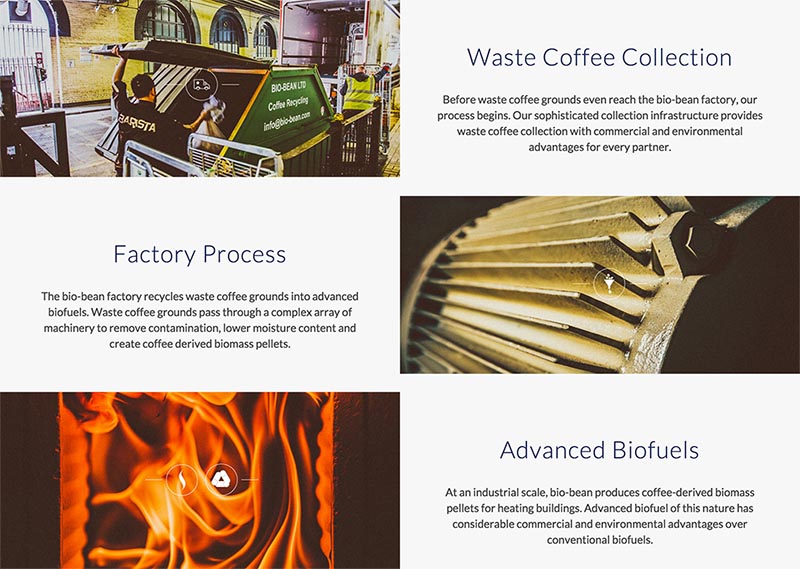

As an architecture student at The Bartlett, UCL, I realised that coffee was being wasted everywhere. Coffee pours out of major urban centres: coffee shops, cafes, office blocks, museums, factories, airports. Anywhere people pass through, huge volumes of coffee grounds were being thrown away into landfill at an enormous economic and environmental cost. In fact, over 500,000 tonnes of waste coffee grounds are produced each year in the UK alone, with 200,000 tonnes from London.

Approaching the problem of coffee waste from an outside perspective, and using sustainability as the driving force behind my ideas, I set out to re-imagine this life cycle. The conceptual leap here was to simply turn this problem on its head. I started with the simple premise that there is no such thing as waste, simply resources in the wrong place.

Coffee waste is transformed into useful energy by bio-bean. Photo credit: bio-bean

In two years, bio-bean has become the first company in the world to industrialise turning waste coffee grounds into advanced biofuels. We have raised several million in finance, built the world’s first waste coffee recycling factory and a team of over twenty people.

[video:https://vimeo.com/151779498]

bio-bean produces biomass pellets, used for heating buildings and in the near future coffee oil that can be refined into biodiesel, used in transport systems. bio-bean’s factory, the first in the world to recycle waste coffee grounds into advanced biofuels at an industrial scale, has the capacity to process 50,000 tonnes of waste coffee grounds each year. That’s one in ten cups of coffee drunk in the UK every year!

bio-bean is a small company interfacing with large corporations that dominate existing systems (such as the waste management industry and coffee supply chain). As the first company in the world to industrialise the process of recycling waste coffee grounds, the policy infrastructure also doesn’t exist to support bio-bean yet. By demonstrating the commercial and environmental advantages of our process has allowed bio-bean to successfully interface with partners at every scale. Most importantly, we have created a fantastic team of people, united under the vision of closing the loop on coffee waste.

The bio-bean process, find out more at bio-bean.com. Credit: bio-bean

bio-bean was set up in response to the challenges of the near future - pollution, transport, housing, food, water, energy, waste, overpopulation, physical and mental well-being equality and climate change - these are not global problems but uniquely urban ones. And if they are caused by cities it will fall to cities to solve them.

The shape of our future and that of our planet depends entirely on how we organise and evolve urban systems. Approaching tomorrow with a spirit of creativity, applying sustainable solutions to create opportunities - this will play a crucial role in all of our futures.

bio-bean is the first company to industrialise the process of recycling waste coffee grounds. Photo credit: bio-bean

****

bio-bean is an award-winning clean technology company that recycles waste coffee grounds into advanced biofuels. To find out more visit: bio-bean.com

Larry Cantwell is the Town Supervisor of East Hampton, a mixed community of baymen and billionaires on Long Island, New York. Cantwell is at the helm as the town embarks on its journey to a sustainable, 100% renewable energy future. The Town Board, energized by community leaders and activists, are taking this bold action following the impact of Superstorm Sandy on East Hampton.

In the past Sumba Island was renowned for being one of the poorest areas of Indonesia where very few people had access to electricity, now thanks to the efforts of Sulis Setiawati the future is looking bright. Setiawati has been at the heart of a groundbreaking, island-wide initiative to address the energy shortage and boost living conditions by going 100% renewable.

Chief Denise Restoule is the leader of the Dokis First Nation community that has existed in harmony with nature on the banks of the French River in Ontario, Canada for time immemorial. For the benefit of her community and the bountiful ecosphere in northern Canada Restoule has catalyzed the Dokis people around a legacy-oriented project - to construct a small hydro-plant and go 100% renewable.

All change needs a champion. Marjina Begum is that champion. She lives in Kulia village in Khulna District, Bangladesh where was the first person to transform her household to run on 100% renew- able energy and is helping other villagers do the same. By harnessing solar energy Begum has avoided the need to rely on patchy grid connections and inefficient kerosene fuel. As a result of her actions local children can now study at night, improving their educational outcomes, women in the village are increasingly empowered, and security has improved.

Whether you’re traveling to work, vacation, or just for a night out, before you reach for those car keys consider these eight benefits of using alternative transportation. Jumping on a train, saddling a bike, or sharing a ride could have payoffs for your health, the planet, and your pocketbook.

Hosted by the World Bank Group and supported by Italy’s Ministry of the Environment and Energy Security and Germany’s Federal Ministry for Economic Cooperation and Development, Connect4Climate (C4C) is a global partnership for a livable planet that connects, creates, and communicates to build long-lasting change for future generations.